Gas cleaning

systems with

energy recovery

Gas cleaning system with energy recovery

etick gas cleaning systems with energy recovery not only ensure compliance with the strictest environmental regulations, but, thanks to our energy recovery technology de recuperación energética, they transform the residual heat from the cremation process into useful energy, providing efficiency, sustainability, and savings in every installation.”

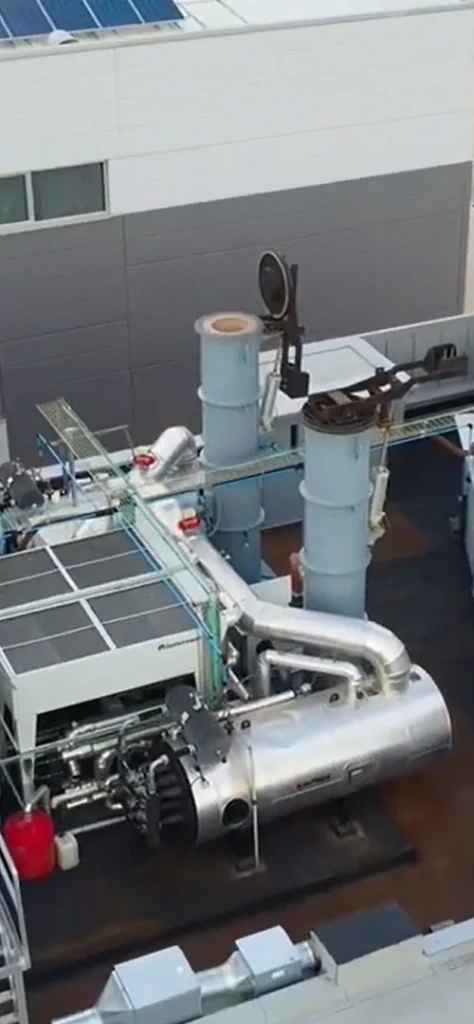

To carry out this process, the combustion gases exiting the furnace are directed to the purification system, with the original chimney maintained as an emergency outlet. Before treatment, the gases pass through an air-to-water heat exchanger that converts thermal energy into usable heat for facility heating or domestic hot water production. When all the recovered heat is not required, an air heater disperses the excess, ensuring the system’s safety and proper operation.

Afterwards, the cooled gases are chemically treated with neutralizing agents and pass through a bag filter that captures solid particles, acidic compounds, heavy metals, dioxins, and furans. The collected residues are then removed by an authorized waste management service.

Finally, an induced-draft fan maintains a steady gas flow and releases the purified, cooled gases into the atmosphere.

All our systems comply with current environmental regulations and respect ethical and cultural considerations, operating with discretion and care

Key benefits:

– Energy savings and reduced overall operating costs.

– Lower CO₂ emissions.

– Improved sustainability of the facility.

– Flexible integration with heating or domestic hot water systems.